Field Fence

12/21/2019

Temporary Fence

12/21/2019

Curvy Welded Fence

Tensile strength: 1.5mm-6.0mm

Wire thickness: window screen, filter.

Customise acceptable

Free sample

Product description: The fence panels are jointed with the post without any clamps, and it is easy and convenient. It could insert into the sew of concrete base of 40mm width. Usually there is the plastic caps on the top.

curved wire mesh fence

1. Material: mild steel wire, aluminum magnesium alloy wire and PVC coated steel wire. low carbon steel wire

2. Process: Wire mesh fence is formed through weaving and welding. The process involves pre-straightening wire, cutting, and welding, inspecting, mounting frame, destructive testing and beautification (PE coating, PVC coating or hot dipping)

3.surface treatment: electric galvanized, hot dippde galvanized, pvc coated(dark green, blue, black)

Characteristics

Anti-corrosion, anti-aging, sun-proof and resistant to elements. Electroplating, hot-dip coating, plastics spraying and dip coating are available for anti-corrosion purposes. Wire mesh fence is firm, durable, rustless and attractive.

Applications: Wire Mesh fence is used for protection in highways, railways, airports, residence communities, ports and piers, gardens and livestock-raising

Colors: Dark green, blue, white, red, yellow, black, grey,ect as your request. Dark Green is the most popular for Exporting.

Surface treatment:electro-galvanized, Hot dipped galvanized, color pvc coated, powder coated.

Process: Welded---making folds/curves ----Parkerizing ---electric galvanized/hot-dipped --- PVC coated/spraying---packing.

Feature:Anti climbing;Different colors make the entire door look beautiful;Anti corrosion, the pvc coated can make its useful years greatly improved;Beautiful appearance, more luster;Powder coated thickness will be 0.3-0.4mm;Price moderate.

Application:Curved welded wire fence is extensively used for protection of airport, ports and harbors, for partition and protection of construction of cities, including gardens, lawn, zoos, pools and lakes.

Fence Panel:

STEP 1: it has rubber mat at the bottom of the pallet to avoid the pallet destroying the panels;

STEP 2: it has 4 metal corners to keep the pallet more strong;

STEP 3: it has metal plate under the plastic bandage to reduce the apressure of fence panels;

STEP 4: it has wooden plate at the top of fence panel which can protect the fence panels avoid being crushed by other pallets.

High Anti-Corrosion:

Using high quality iron rod as raw material, the welded panel, after galvanization, powders primer, and powders top coating, it can resist the corrosive and ultraviolet radiation very strongly.

1. Material: mild steel wire, aluminum magnesium alloy wire and PVC coated steel wire. low carbon steel wire

2. Process: Wire mesh fence is formed through weaving and welding. The process involves pre-straightening wire, cutting, and welding, inspecting, mounting frame, destructive testing and beautification (PE coating, PVC coating or hot dipping)

3.surface treatment: electric galvanized, hot dippde galvanized, pvc coated(dark green, blue, black)

Characteristics

Anti-corrosion, anti-aging, sun-proof and resistant to elements. Electroplating, hot-dip coating, plastics spraying and dip coating are available for anti-corrosion purposes. Wire mesh fence is firm, durable, rustless and attractive.

Applications: Wire Mesh fence is used for protection in highways, railways, airports, residence communities, ports and piers, gardens and livestock-raising

Colors: Dark green, blue, white, red, yellow, black, grey,ect as your request. Dark Green is the most popular for Exporting.

Surface treatment:electro-galvanized, Hot dipped galvanized, color pvc coated, powder coated.

Process: Welded---making folds/curves ----Parkerizing ---electric galvanized/hot-dipped --- PVC coated/spraying---packing.

Feature:Anti climbing;Different colors make the entire door look beautiful;Anti corrosion, the pvc coated can make its useful years greatly improved;Beautiful appearance, more luster;Powder coated thickness will be 0.3-0.4mm;Price moderate.

Application:Curved welded wire fence is extensively used for protection of airport, ports and harbors, for partition and protection of construction of cities, including gardens, lawn, zoos, pools and lakes.

Fence Panel:

STEP 1: it has rubber mat at the bottom of the pallet to avoid the pallet destroying the panels;

STEP 2: it has 4 metal corners to keep the pallet more strong;

STEP 3: it has metal plate under the plastic bandage to reduce the apressure of fence panels;

STEP 4: it has wooden plate at the top of fence panel which can protect the fence panels avoid being crushed by other pallets.

High Anti-Corrosion:

Using high quality iron rod as raw material, the welded panel, after galvanization, powders primer, and powders top coating, it can resist the corrosive and ultraviolet radiation very strongly.

| Surface Treatment | Min. | Max. |

| Electric Gal. | 20/m2 | 60g/m2 |

| Hot dipped Gal. | 35g/m2 | 700g/m2 |

| Powders Sprayed coating | 100 microns | 120 microns |

| PVC/PE dipped coating | 400 microns | 600 microns |

Design Advantage:

The fence panels are jointed with the post without any clamps, and it is easy and convenient. It could insert into the sew of concrete base of 40mm width. Usually there is the plastic caps on the top of the post. The upper examine and repair is very easy, and the posts are easy to replace.

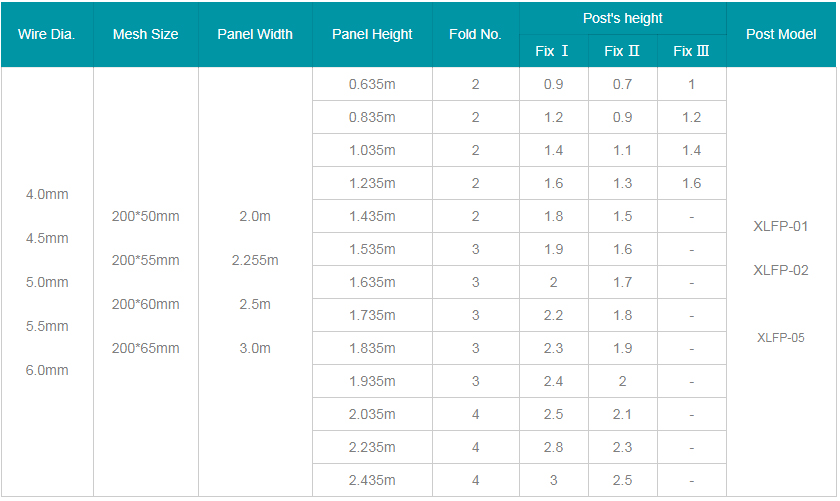

Popular Specification:

The fence panels are jointed with the post without any clamps, and it is easy and convenient. It could insert into the sew of concrete base of 40mm width. Usually there is the plastic caps on the top of the post. The upper examine and repair is very easy, and the posts are easy to replace.

Popular Specification:

| Wire Dia. | Mesh Size | Panel Width | Panel Height | Fold No. | Post's height | Post Model | ||

| Fix Ⅰ | Fix Ⅱ | Fix Ⅲ | ||||||

| 4.0mm 4.5mm 5.0mm 5.5mm 6.0mm |

200*50mm 200*55mm 200*60mm 200*65mm |

2.0m 2.255m 2.5m 3.0m |

0.635m | 2 | 0.9 | 0.7 | 1 | XLFP-01 XLFP-02 XLFP-05 |

| 0.835m | 2 | 1.2 | 0.9 | 1.2 | ||||

| 1.035m | 2 | 1.4 | 1.1 | 1.4 | ||||

| 1.235m | 2 | 1.6 | 1.3 | 1.6 | ||||

| 1.435m | 2 | 1.8 | 1.5 | - | ||||

| 1.535m | 3 | 1.9 | 1.6 | - | ||||

| 1.635m | 3 | 2 | 1.7 | - | ||||

| 1.735m | 3 | 2.2 | 1.8 | - | ||||

| 1.835m | 3 | 2.3 | 1.9 | - | ||||

| 1.935m | 3 | 2.4 | 2 | - | ||||

| 2.035m | 4 | 2.5 | 2.1 | - | ||||

| 2.235m | 4 | 2.8 | 2.3 | - | ||||

| 2.435m | 4 | 3 | 2.5 | - | ||||

Click picture to see more specifications

00%